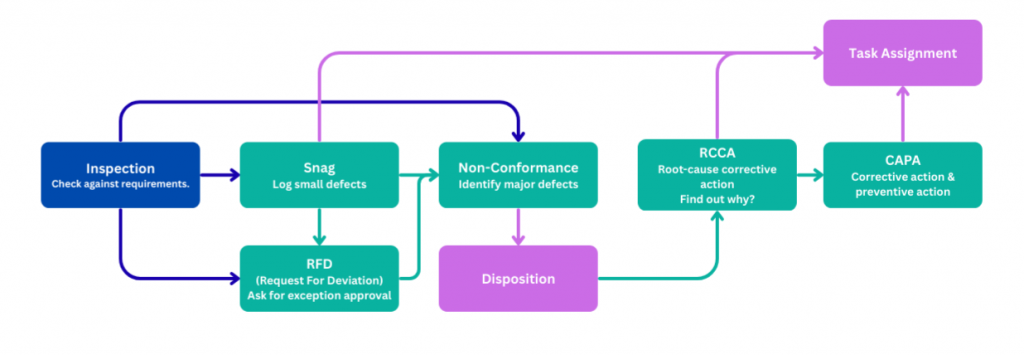

Quality control is often misunderstood as “inspection at the end.” In reality, effective QC is a connected workflow; one that starts with inspection and continues through issue tracking, decision-making, corrective action, and accountability.

Modern manufacturers and operations teams need more than checklists and spreadsheets. They need a systematic quality control process, supported by software, that ensures issues are captured early, managed consistently, and resolved permanently.

This article explains the end-to-end QC process and shows how each step is supported inside Artintech ERP.

Step 1: Inspection: The Foundation of Quality Control #

Every quality control process starts with inspection.

Inspections verify whether products, materials, or processes meet defined requirements such as:

Technical specifications

Customer requirements

Regulatory or industry standards

Internal quality criteria

Inspections can happen at multiple points:

Incoming materials

In-process production

Final product release

Field or service activities

How software helps #

With Artintech ERP Inspection Forms, inspections are:

Standardized and repeatable

Linked to sales orders, batches, or assets

Fully traceable for audits and reporting

Inspection data becomes structured quality intelligence, not scattered notes.

Step 2: Snag, Capturing Minor Issues Before They Escalate #

Not every issue requires a full non-conformance. This is where snags come in.

A snag is a minor defect or issue identified during inspection that:

Does not immediately block operations

Does not pose a safety or compliance risk

Still requires correction

Common examples include:

Cosmetic defects

Minor dimensional adjustments

Missing labels or markings

Small documentation gaps

Why snag tracking matters #

Organizations that ignore small issues usually face bigger ones later. Capturing snags early:

Prevents rework accumulation

Improves consistency

Strengthens quality culture

How software helps #

The Snag Form in Artintech ERP allows teams to:

Log issues quickly

Link them to inspections

Track closure without unnecessary escalation

This keeps quality proactive instead of reactive.

Step 3: Non-Conformance, When Requirements Are Not Met #

A Non-Conformance (NC) is raised when a product or process fails to meet a defined requirement.

Non-conformances may originate from:

Failed inspections

Customer complaints

Internal audits

Process breakdowns

An NC formally documents:

What requirement was violated

Where and how it occurred

Scope and impact

Immediate containment actions

How software helps #

Using Artintech ERP’s Non-Conformance Form, organizations can:

Standardize NC classification

Maintain audit-ready records

Link issues to root cause and CAPA workflows

This ensures quality decisions are based on evidence, not assumptions.

Step 4: Request for Deviation, Managing Approved Exceptions #

In some cases, a product does not fully meet requirements, but scrapping or reworking is not the best option. A Request for Deviation (RFD) allows organizations to formally approve and control exceptions.

A deviation is:

Intentional and documented

Approved by authorized roles

Time-limited or quantity-limited

Fully traceable

Examples include:

Temporary dimensional tolerance approval

Use-as-is decisions

Temporary process changes

How software helps #

The Request for Deviation Form in Artintech ERP:

Enforces approval workflows

Documents risk and justification

Links deviations back to non-conformances

This eliminates informal approvals that fail audits.

Step 5: Disposition, Deciding What to Do with Non-Conforming Output #

Once a non-conformance is identified, a disposition decision must be made.

Typical disposition options include:

Rework

Repair

Scrap

Return to supplier

Use as is (with deviation approval)

Disposition answers the operational question:

What happens to this product right now?

How software helps #

The Disposition Form in Artintech ERP:

Records decisions and authorizations

Separates immediate actions from long-term improvements

Triggers follow-up tasks automatically

This avoids confusion between fixing the product and fixing the process.

Step 6: RCCA, Identifying Root Causes #

Fixing symptoms is not quality improvement. Root Cause & Corrective Action (RCCA) focuses on why the issue happened and why it was not prevented earlier.

RCCA typically examines:

Process weaknesses

Human factors

Equipment or tooling issues

Training gaps

Control failures

How software helps #

The RCCA Form in Artintech ERP:

Structures root-cause analysis

Links causes to evidence

Connects analysis directly to CAPA planning

This turns investigations into actionable insight.

Step 7: CAPA, Corrective and Preventive Action #

CAPA is where quality control delivers long-term value.

Corrective actions eliminate root causes of existing problems

Preventive actions reduce the likelihood of similar issues elsewhere

Effective CAPAs are:

Clearly defined

Assigned to owners

Time-bound

Verified for effectiveness

How software helps #

With Artintech ERP’s CAPA module, organizations can:

Track actions to completion

Verify effectiveness with evidence

Maintain full traceability from issue to resolution

This is how quality systems mature over time.

Step 8: Task Assignment, Turning Quality Decisions into Action #

Quality processes fail when actions are not owned.

Every inspection finding, correction, or CAPA requires:

Assigned responsibility

Due dates

Status tracking

Visibility

How software helps #

The Task Assignment feature in Artintech ERP:

Links quality actions to real people

Integrates QC tasks into daily operations

Ensures accountability and follow-through

Quality becomes executable, not theoretical.

Why an Integrated QC/QMS Software Matters #

Without an integrated quality management system (QMS), quality workflows become:

Fragmented across emails and spreadsheets

Difficult to audit

Hard to analyze for trends

Dependent on individual discipline

With Artintech ERP, the entire QC process—from Inspection to Snag, Non-Conformance, Deviation, RCCA, CAPA, and Task Assignment—is:

Fully connected

Traceable

Audit-ready

Scalable

This allows organizations to move from reactive quality control to systematic quality improvement.