The order-to-cash process, often called O2C, covers everything from receiving a customer order to collecting payment for the delivered goods or services. A clear O2C cycle helps maintain accurate order handling, improves customer satisfaction, and strengthens cash flow.

This guide explains each stage in simple terms and shows how Artintech ERP supports the workflow without turning the article into a product pitch.

What Is the Order-to-Cash Process? #

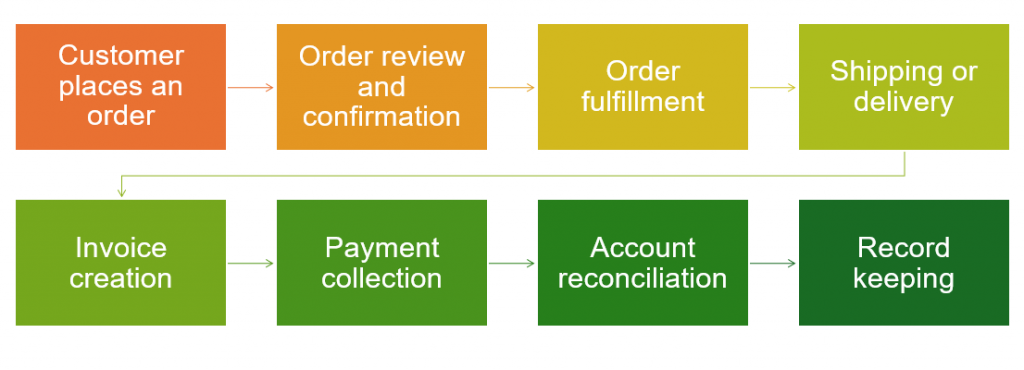

Order-to-cash includes the full sequence of activities that start when a customer places an order and end when the payment is received and recorded.

It connects sales, fulfillment, shipping, invoicing, and finance in one continuous flow.

Why the O2C Cycle Matters #

A smooth O2C process helps:

reduce errors in customer orders

improve delivery accuracy

support faster invoicing and payment

strengthen customer relationships

provide clear financial visibility

Step-by-Step Order-to-Cash Workflow #

1. Customer Places an Order #

The O2C cycle begins when a customer submits an order for goods or services. This may come through email, online forms, phone, sales representatives, or integrated ordering platforms. At this stage, accuracy is important: item details, quantities, delivery addresses, pricing, and terms must be captured correctly. A clear and complete order helps avoid delays, reduces follow-up questions, and ensures expectations are aligned.

With Artintech ERP: Customer orders can be entered directly into the system with accurate customer data, pricing rules, and item details pulled from master records.

2. Order Review and Confirmation #

Once the order is received, the sales or customer service team reviews it to confirm availability, pricing, delivery dates, and any required specifications. This check ensures that the company can commit to the order as requested. If adjustments are necessary—such as alternative delivery dates or partial fulfillment—the team communicates these updates before confirming the order.

With Artintech ERP: Teams can review stock levels, pricing, discounts, and customer history in one place to confirm the order confidently.

3. Order Fulfillment #

After confirmation, the warehouse or operations team prepares the items for delivery. This includes picking, packing, checking quantities, and ensuring the correct items are included. For service-based orders, fulfillment may involve assigning a technician, scheduling work, or preparing deliverables. Proper fulfillment helps maintain accuracy and avoids returns or issues later in the process.

With Artintech ERP: Warehouse staff can access pick lists, packing slips, and stock locations to prepare orders efficiently and accurately.

4. Shipping or Delivery #

Items are shipped to the customer using the selected delivery method. Tracking numbers, carriers, and expected delivery dates are documented and shared when needed. Clear and timely shipping supports good customer experience and reduces uncertainty.

With Artintech ERP: Shipment details can be recorded directly, linking tracking numbers and carrier information to the order for easy reference.

5. Invoice Creation #

Once the order is shipped or delivered, an invoice is generated and sent to the customer. The invoice includes item details, prices, taxes, delivery dates, and payment terms. Prompt and accurate invoicing helps reduce delays in receiving payment and supports consistent cash flow.

With Artintech ERP: Invoices can be generated automatically from the fulfilled order, ensuring all details match without manual entry.

6. Payment Collection #

The customer pays the invoice using the agreed method—such as bank transfer, credit card, or other payment options. The accounts team monitors outstanding invoices, follows up when needed, and records incoming payments. Timely payment collection improves liquidity and supports financial stability.

With Artintech ERP: Payments can be recorded directly, updating customer balances and linking each payment to the related invoice.

7. Account Reconciliation #

After payments are received, financial records are updated to ensure everything matches. This includes verifying that invoices are fully paid, checking for partial payments or discrepancies, and confirming that revenue is recorded correctly. Accurate reconciliation strengthens reporting and ensures financial transparency.

With Artintech ERP: All order, invoice, and payment records remain connected, making reconciliation simple and reducing manual work.

8. Record Keeping and Customer History #

The final step involves keeping complete records of the order, shipment, invoice, and payment. These records support audits, future sales activities, customer service, and business analysis. A full history helps teams understand customer buying patterns, resolve disputes, and plan future inventory or sales strategies.

With Artintech ERP: Every document remains stored and linked, offering a complete timeline for each customer transaction.