Manage BOMs, Manufacturing Orders, and Production Processes with Artintech

Make sure your manufacturing processes are well-managed. Create and manage your bills of materials and manufacturing orders and automatically have your input and output inventory updated.

Optimize Your Manufacturing Processes with Artintech Resource Planning Software

Artintech production and manufacturing process management software provides a comprehensive solution for businesses looking to streamline their manufacturing processes. With features such as Bill of Materials (BOM), Manufacturing Order, end product cost of material calculation, and raw material shortage report, Artintech helps you manage your production schedules more effectively and improve your overall efficiency. Whether you are a small or large-scale manufacturer, Artintech manufacturing resource planning software can help you optimize your production operations, reduce waste, and increase profitability. With a user-friendly interface and reporting options, Artintech is the ideal solution for businesses looking to stay competitive in today’s fast-paced manufacturing environment.

-

Bill of Materials (BOM)

Create the recipe of your products for your assembly line or manufacturing processes. Know exactly what you need to manufacture your finished (or semi-finished) goods.

-

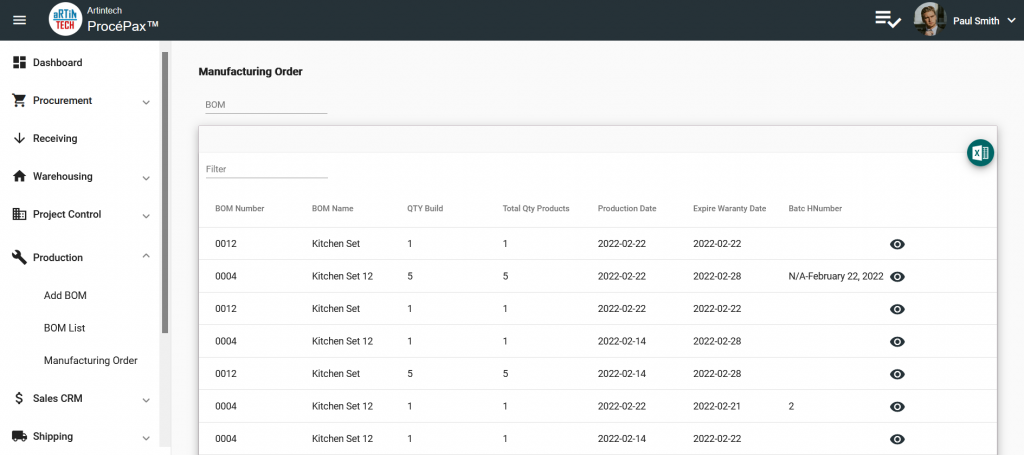

Manufacturing Order (MO)

Create a manufacturing order and plan for your operations. Manage the resources you need to create the final goods.

-

Work in Progress (WIP)

Check the status of the production. Manage your work in progress and the material being used throughout your manufacturing process.

Best Matching Modules

Most of our clients match this module with the modules below to best optimize their business processes.

90 days free trial! No credit card required.

Start streamlining your processes!

Get started with Artintech today and streamline your business operations. Sign up now to achieve your business goals with our powerful suite of modules.