The procure-to-pay process, often called P2P, covers everything from identifying a need inside a company to paying the supplier who fulfills that need. A clear P2P cycle helps teams reduce mistakes, improve accuracy, and keep spending organized.

This guide explains each step in plain language.

What Is the Procure-to-Pay Process? #

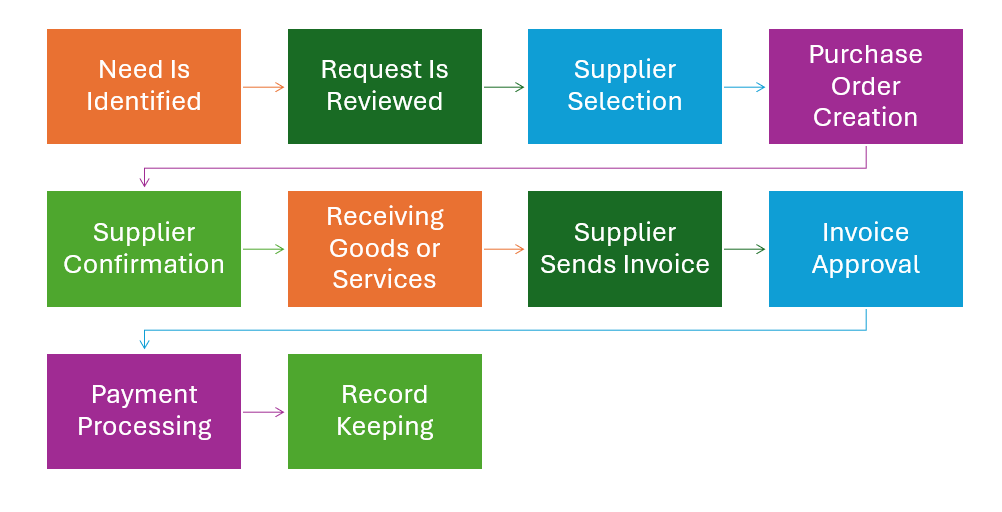

Procure-to-pay is the full workflow used to request items, choose suppliers, create purchase orders, receive goods or services, match invoices, and complete payments. It connects procurement with accounts payable.

Why the P2P Cycle Matters #

A good P2P process helps:

Control purchasing activities

Avoid duplicate or incorrect orders

Improve tracking of inventory and expenses

Simplify invoice matching

Keep supplier payments accurate and timely

Step-by-Step Procure-to-Pay Workflow #

1. Need Is Identified #

The procure-to-pay cycle begins when a team realizes they require something to support ongoing work. This could be raw materials for production, packaging supplies, replacement parts, tools, software subscriptions, or even external services. At this stage, the focus is simply on recognizing a need that affects operations, schedules, or inventory levels. Clear identification helps avoid delays, prevents last-minute purchases, and ensures that requests are aligned with project or department goals.

With Artintech ERP: This step become automatic! In the “Reorder List” page, purchasing manager can see all the items that are needed and are below the reorder point. This means someone in the company needs such products either for sales, production, work orders, or projects. Otherwise, the internal communication board or even task manager can be used to notify the procurement department of the need for products, parts, tools, and so on.

2. Request Is Reviewed #

Once a need has been identified, the request moves to an approval stage where managers or supervisors examine the details. The goal is to confirm that the request is necessary, aligned with budgets, and correctly specified. This review helps prevent duplicate orders, overspending, or purchasing the wrong items. Approvers may verify quantities, check stock levels, consider alternatives, or adjust priorities based on workload or financial planning. A clear review process ensures accountability and keeps procurement activities consistent across departments.

With Artintech ERP: Approvers can review all request details, add notes, and approve or reject the request directly in the system, keeping decisions organized and easy to track. This can be in the form of notes or attachments inside PO, Quote, or Task detail.

3. Supplier Selection #

After a request is approved, the purchasing team evaluates potential suppliers who can provide the required items or services. This step involves reviewing approved vendor lists, comparing prices, checking product specifications, and confirming delivery timelines. Teams may also consider factors such as supplier reliability, past performance, quality records, and any existing contracts or negotiated terms. Choosing the right supplier helps reduce risks, maintain quality standards, and ensure that deliveries arrive when needed. A careful selection process strengthens long-term supplier relationships and supports consistent procurement outcomes.

With Artintech ERP: Supplier profiles, quote history, lead times, and past purchase records are available in one place to help teams select the most suitable vendor quickly and confidently.

4. Purchase Order (PO) Creation #

Once the supplier is selected, the next step is to formalize the request through a purchase order (PO). A PO outlines exactly what the company intends to buy, including item descriptions, quantities, prices, delivery terms, and any required instructions. This document serves as an official agreement between the buyer and the supplier, ensuring both sides have a clear and consistent understanding of the order. Creating a precise and accurate PO helps prevent miscommunication, reduces the risk of incorrect deliveries, and provides a reliable reference for future verification during receiving and invoicing stages.

With Artintech ERP: The approved request can be converted into a purchase order automatically, reducing manual typing and ensuring all key details are carried forward accurately. Users can then review, finalize, and send the PO to the supplier.

5. Supplier Confirmation #

After receiving the purchase order, the supplier reviews the details to ensure that everything is accurate and achievable. They check item availability, quantities, pricing, and delivery timelines before confirming the order. If adjustments are needed—such as changes in delivery dates, substitutions, or pricing updates—the supplier communicates these before moving forward. This confirmation step is important because it aligns expectations between both parties and prevents delays or misunderstandings later in the process. A clear confirmation provides reassurance that the order is accepted and on track.

With Artintech ERP: Any supplier updates or confirmations can be logged directly into the purchase order record, helping your team keep track of changes and always see the most current information.

6. Receiving Goods or Services #

Once the supplier ships the order, the receiving team checks the delivery upon arrival. This includes verifying that the correct items were delivered, quantities match the purchase order, and the condition of the goods meets expected quality standards. If the delivery contains materials, parts, or equipment, the receiving staff may also record batch numbers, serial numbers, or expiry dates. When services are delivered instead of physical goods, the team confirms that the work was completed as agreed. This step ensures accuracy, avoids paying for incomplete or incorrect deliveries, and prepares the organization for the next stage of the procure-to-pay cycle.

With Artintech ERP: Users can record goods receipt details directly in the system, including quantities received, batch information, and any quality notes, keeping the receiving process organized and traceable.

7. Supplier Sends Invoice #

After the goods or services have been delivered, the supplier issues an invoice requesting payment. This document typically includes the purchase order number, item descriptions, quantities, prices, taxes, and any additional charges. The finance or accounts payable team reviews the invoice to ensure it accurately reflects what was ordered and received. This step is essential to prevent paying for incorrect quantities, wrong prices, or items that were never delivered. Clear invoice handling helps maintain financial accuracy and supports smooth payment processing.

With Artintech ERP: Invoices can be matched against the corresponding purchase order and goods receipt using a three-way match, helping your team quickly verify accuracy before moving to approval.

8. Invoice Approval #

Once the invoice has been verified, it moves through the organization’s approval workflow. Approvers review the details to confirm that the charges are correct, the delivery was completed satisfactorily, and the expense aligns with budgets or project requirements. This step adds accountability and ensures that payments are authorized only when everything checks out. A clear approval process also helps prevent duplicate payments, unexpected spending, and financial discrepancies. When the invoice is approved, it becomes ready for final payment processing.

With Artintech ERP: Approvers can review invoices, add notes, and approve them directly in the system, keeping the approval trail organized and easy to follow.

9. Payment Processing #

Once the invoice is approved, the final step is to issue payment to the supplier according to the agreed terms. This may involve bank transfers, cheques, electronic payment systems, or other methods depending on company policy. During this stage, the finance team ensures payments are scheduled on time, recorded correctly, and aligned with cash flow planning. Accurate payment processing strengthens supplier relationships, helps maintain good credit standing, and ensures the company meets its contractual commitments. Proper documentation at this step also supports clear audit trails and simplifies future financial reviews.

With Artintech ERP: Payment entries can be recorded directly in the system, updating supplier balances and linking the payment to the related invoice and purchase order for complete traceability.

10. Record Keeping #

After the payment is completed, all related documents—such as the purchase request, purchase order, supplier confirmation, goods receipt, invoice, and payment record—need to be stored in an organized way. Proper record keeping ensures that the company maintains clear financial and operational history. These records help during audits, support future supplier negotiations, assist with budgeting and forecasting, and provide a reference when similar purchases are made later. Having accurate and accessible documentation strengthens accountability and improves transparency across the entire procure-to-pay cycle.

With Artintech ERP: All documents and transaction details remain linked and stored within the system, making it easy to review past purchases, trace information, and prepare for audits without searching through separate folders or files.

Best Practices for Teams Using P2P #

Keep supplier information updated

Set clear approval rules

Monitor lead times regularly

Use a standard naming or numbering structure

Use reporting dashboards to watch spending trends