Make to Order (MTO) Manufacturing Solution

Discover the efficiency of Make-to-Order (MTO) solutions with Artintech ERP. Our platform integrates all stages of MTO manufacturing – from sales and order processing to production and shipping. With features for real-time order tracking, inventory management, and production planning, Artintech ERP ensures a seamless, efficient manufacturing process.

Make to Order (MTO) Process:

System Setup

- Suppliers

- Customers

- Items

- Warehouses

- Staff

- Organization

- Project Templates

Monitoring & Control

- Sales Reports

- Financial Reports

- Inventory Reports

- Management Reports

Make to Order (MTO) steps:

The Made-to-Order (MTO) manufacturing process involves creating products based on specific customer requirements. Here are the general steps involved in the MTO manufacturing process:

Customer Order: The process begins when a customer places an order for a specific product. The order includes specific details about the product, such as size, color, material, and other customizations.

Order Review: The manufacturer reviews the order to ensure they have the necessary resources to fulfill it. This includes checking the availability of materials, labor, and machinery.

Planning and Design: Based on the customer’s specifications, the manufacturer plans and designs the product. This may involve creating a new design or modifying an existing one.

Procurement of Materials: If the manufacturer doesn’t have the necessary materials on hand, they will need to procure them. This involves ordering the materials from suppliers and waiting for their delivery.

Production: Once all materials are available, the production process begins. This involves various stages such as cutting, shaping, assembling, and finishing, depending on the nature of the product.

Quality Control: After the product is manufactured, it undergoes quality control checks to ensure it meets the customer’s specifications and the manufacturer’s quality standards.

Delivery: Once the product passes the quality control checks, it is packaged and delivered to the customer.

It’s important to note that the specific steps can vary depending on the industry and the nature of the product being manufactured.

Examples of industries with Make to Order (MTO) manufacturing process:

For the Make-to-Order (MTO) manufacturing approach, which involves producing goods based on specific customer orders, here are sub-industries where Artintech ERP could be beneficial:

Custom Furniture Manufacturing

- Custom Kitchen Cabinets and Countertops

- Bespoke Upholstered Furniture

- Handcrafted Wooden Furniture

- Custom Office Furniture

- Custom Outdoor Furniture

Custom Apparel Manufacturing

- Made-to-Measure Tailoring

- Custom Wedding Dresses and Bridal Wear

- Bespoke Men’s Suit Manufacturing

- Custom Athletic Apparel

- Luxury Fashion Customization

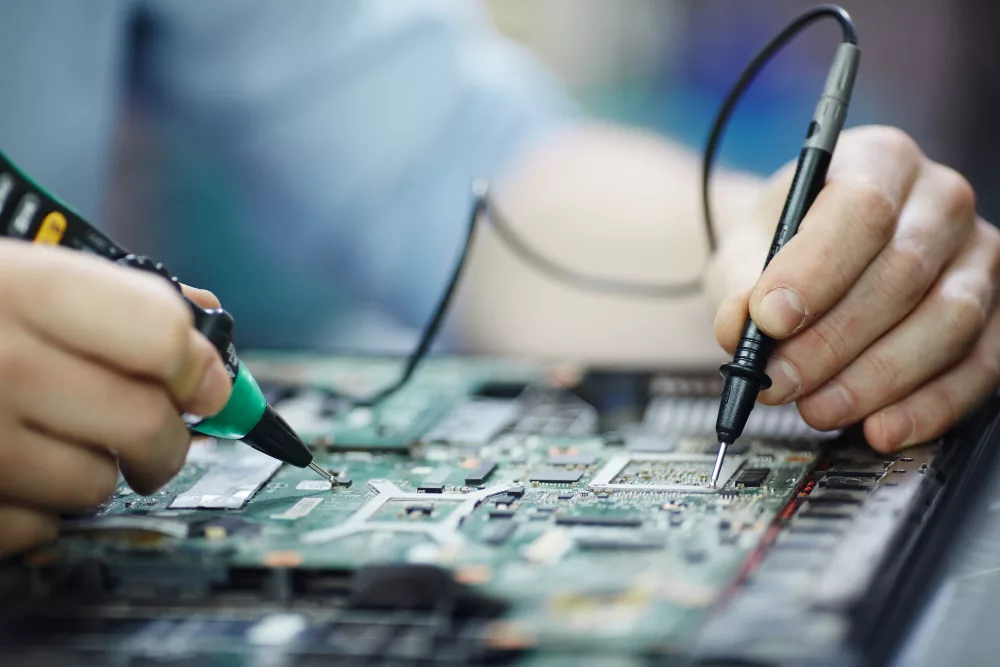

Custom Electronics Manufacturing

- Customized PC and Gaming Systems

- Personalized Consumer Electronics (e.g., Customized Smartphones)

- Custom Audio Equipment Manufacturing

- Custom Industrial Control Systems

- Bespoke IoT (Internet of Things) Devices

Custom Jewelry Manufacturing

- Custom Engagement Rings and Wedding Bands

- Personalized Engraved Jewelry

- Bespoke Fine Jewelry Design

- Custom Birthstone Jewelry

- Handcrafted Artisan Jewelry

Custom Packaging Manufacturing

- Custom Printed Cardboard Boxes

- Personalized Luxury Gift Packaging

- Custom Branded Product Packaging

- Custom Food Packaging Solutions

- Bespoke Packaging for Promotional Items

In each of these sub-industries, Artintech ERP’s modules, such as manufacturing, project control, quality management, and supply chain management, can support the MTO approach by streamlining order management, improving production efficiency, ensuring quality control, and managing the supply chain to meet customer-specific requirements.

90 days free trial! No credit card required.

Start streamlining your processes!

Get started with Artintech ERP today and streamline your business operations. Sign up now to achieve your business goals with our powerful suite of modules.